The factory floor is a complex, multilayered environment that is difficult to navigate and manage. There are many ways to improve efficiency on the factory floor, but one of the most effective is using real-time location (RTLS) systems. RTLS systems allow factories to track the position of workers in real-time and automatically adjust their workstations based on their location and proximity to other workers.

Real-time location systems (RTLS) use sensors and software mounted on robots or machines to track the movement of people, equipment, or objects within a facility. The data collected by these sensors can be used to detect potential safety hazards or equipment issues before they become major problems.

Here are ways in which real-time location systems are revolutionizing manufacturing;

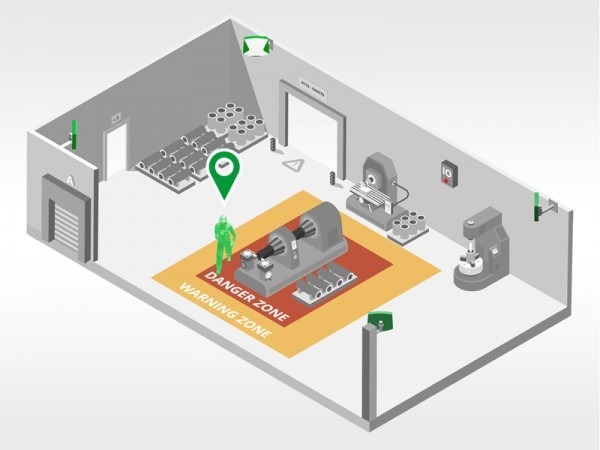

1. Helps improve safety

The drawback of many industrial robots is their inability to navigate unfamiliar settings. This can pose a serious risk to workers and slows down production. Real-time location systems (RTLS) can provide factory managers with the necessary data to ensure workers are safely moving around the factory floor hence improving manufacturing facility safety. That means fewer injuries, fewer lost hours at work, and higher productivity for everyone.

2. Reduces training time

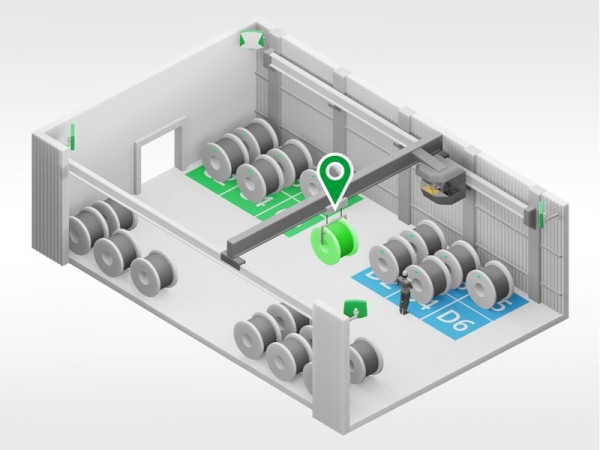

RTLS can help reduce training time for new or current employees who want to learn new skills on the job. When you have an accurate map of your facility, you can see where everything is located and where it should be going without relying on someone else’s memory or experience.

3. Improves overall efficiency

RTLS improves overall efficiency throughout your entire manufacturing facility by allowing workers to be more productive without spending time tracking down each piece of equipment manually or relying on someone else’s memory or experience.

4. Helps managers to oversee operations

RTLS allows users to monitor their employees’ movements around the facility and see when they leave their designated areas; it also gives managers a better idea of how long each worker will take to complete their tasks at each station on the factory floor. This information can help managers determine how much time each worker needs.

5. Boost productivity

Real-time location systems (RTLS) help boost factory floor productivity by improving efficiency, safety, and quality. It’s no secret that manufacturing is one of the most energy-intensive industries in the world. It’s also one of the most economically important without proper planning and coordination. However, manufacturers can experience significant losses due to wasted labor or production time.

6. Ensure compliance with company safety policies

Real-time location systems have become integral to a manufacturing facility’s operating system. The technology allows operators to monitor and control their production line remotely, ensuring that everything runs smoothly and that workers are not in unsafe locations.

7. Provide better insights into operations

The data collected by RTLS systems provide valuable insights into the working conditions on a factory floor. Using this information, companies can improve productivity by identifying issues with machines and equipment, identifying where resources are needed, and even determining whether there are any problems with the workers or their job skills. They can also use this information to determine how much time employees spend idle and what changes should be made to increase efficiency or reduce waste of materials.

8. Help reduce accidents

Using RTLS, workers can stay safer on the factory floor by monitoring their location and keeping track of their movement. This helps prevent accidents, which significantly impact worker productivity and efficiency. For example, an average worker can lose eight hours yearly due to slip and fall injuries. By using RTLS solutions, workers can avoid these types of injuries altogether.

9. Quick response during emergencies

Real-time location systems also allow for quick response in case of an emergency. The system can inform production managers when a worker has left their post or needs assistance, allowing them to send them back to their station or provide other assistance as needed.

10. Improve quality

When employees use RTLS systems to navigate around the factory floor, it helps them focus on what they’re doing instead of constantly checking their cell phones or other devices for directions or instructions. This gives workers more time to think about their work, making them more efficient and effective. As a result, less waste occurs due to mistakes or oversights during production, and so does higher-quality output.

11. Help optimize processes

Real-time location systems (RTLS) are revolutionizing manufacturing by enabling companies to optimize processes on the factory floor. A recent study found that more than one-third of surveyed companies have implemented RTLS, hence improving manufacturing workflows.

Key Takeaway

The factory floor is a complex environment, and finding the right equipment, people and processes to drive efficiency is not always easy. But with real-time location systems (RTLS), manufacturers can get the most out of their factories with the right information at the right time. RTLS solutions are enabling companies to boost efficiency on the factory floor.