Aluminum foil is such a versatile and widely used material, yet many of us don’t know how it’s made. From pizza boxes to insulated lunch bags, it turns out there’s a lot more produced in an aluminum foil factory than you might think! So, in this blog post, we’ll take a look inside such an enterprise and discover the amazing products it makes.

Table of Contents

- Household aluminum foil

- Commercial aluminum foil

- Heat transfer foil

- Electrical conductors

- Decorative aluminum foil

- Conclusion

Household aluminum foil

Household aluminum foil is a lightweight material, often used for cooking and freezing food. It is typically made from alloy 1100, which consists of 99.3% aluminum and 0.7% other metals, and can be found in thicknesses from as thin as 9 microns to as thick as 25 microns. Note that the thinner the foil, the more easily it will bend and conform to the shape of whatever it is covering.

In most cases, household aluminum foil is used to cover food when baking, roasting, grilling, or reheating in the oven. At the same time, it can also be used to wrap food, providing a layer of protection that prevents food from drying out. Lastly, aluminum foil can even be used to make cooking utensils such as foil packets or wrappers for grilling vegetables or fish.

Commercial aluminum foil

Commercial aluminum foil is an essential product used in a variety of industries including food service, baking, packaging, insulation, and more. These foils are usually thicker than household ones since they are designed to withstand the rigors of commercial use and can be used to wrap foods for storage and cooking, or even as containers for take-out meals. Additionally, they may also serve as a versatile material in packaging applications, as they provide a barrier to oxygen, moisture, and other contaminants. For this reason, commercial aluminum foil is widely adopted in the pharmaceutical industry for packaging drugs, tablets, capsules, and medical devices. Besides, it’s employed for lining bags, lunch boxes, and pouches for products such as pet food or snacks.

The most common form of commercial aluminum foil is 12-inch wide rolls with a thickness of 0.0015 inches that can also be custom cut to meet customer specifications. Thus, such foils can be printed with logos and images for promotional purposes or can be pre-cut for a variety of packaging applications.

Heat transfer foil

This kind of foil is made from thin sheets of metal that are highly resistant to heat and cold, making them an ideal choice for transferring energy from hot to cold surfaces, as well as reducing energy losses.

For the most part, heat transfer foil is used in air conditioning units, refrigerators, and even solar panels. Plus, it could be utilized as a protective barrier in construction projects, for example, to wrap pipes and ducts that are exposed to outside temperatures.

To conclude, this type of aluminum foil is usually inexpensive, showcasing a lightweight and non-flammable nature, making it a safe choice for many environments.

Electrical conductors

Aluminum foil factories also manufacture electrical conductors which are vital for wire insulation, shielding, and electrical components to be used as protection against radio frequency interference, as well as electromagnetic one.

The aluminum foil used for electrical conductors is typically made of a high-purity alloy of aluminum to ensure the electrical current runs efficiently through the foil without any resistance. In addition, the thickness of the foil also needs to be taken into account, as it will determine how much electricity can pass through it and whether or not an efficient current flow will be generated.

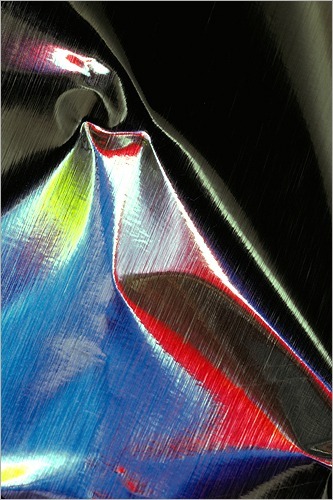

Decorative aluminum foil

This type of foil is a versatile material used for craft projects, decorations, and gifts, whose lightweight, yet durable design allows for easy manipulation, cutting, and shaping. Decorative aluminum foil, in particular, can be used to create beautiful artwork and sculptures and is available in a variety of colors, textures, and thicknesses.

Plus, because the aluminum foil is resistant to heat and moisture, it can also be used to create durable jewelry, cards, and other items that need to withstand harsh conditions, for instance, decorative lampshades or gift boxes.

Conclusion

Aluminum foil has become a ubiquitous part of modern life, produced by numerous factories across the globe. With so many applications of household, commercial, heat transfer, and decorative types of aluminum foil, which can also be used as an electrical conductor to boot, it is no wonder that this invention will remain a necessary item for many homes and businesses in years to come.