When most of us picture a ninja sword, we see that unmistakably straight blade sitting hot on an action-movie back. It looks nothing like the long, elegant curve of a samurai katana, and that difference tells us a lot about how each warrior approached a fight. The ninja sword’s flat edge wasn’t a happy accident by some tired blacksmith—it was a smart fix for a life built on secrecy and speed.

How Ninja Weapons Came to Be

Ninja blades first hit the scene during Japan’s wild medieval years, when spies and hit-and-run fighters were often the difference between winning a tight battle or losing a province. Unlike samurai, bound to follow polite dueling rules inside armor and courtyards, shinobi sometimes had to slip through shadows, scale walls, or disappear in a hurry. Because of that, their gear—from shuriken to rope ladders—had to pull double or even triple duty.

Edo-period scrolls and later documents show us that these warriors wanted their swords to be as useful as a Swiss Army knife. They needed edges that bit through cloth, twisted on timber, and jibbed into footholds when a building had to be climbed in the dead of night. A straight blade fit neatly into those chores because its clean spine was easier to grind, repair, or even hide than a gently curved one.

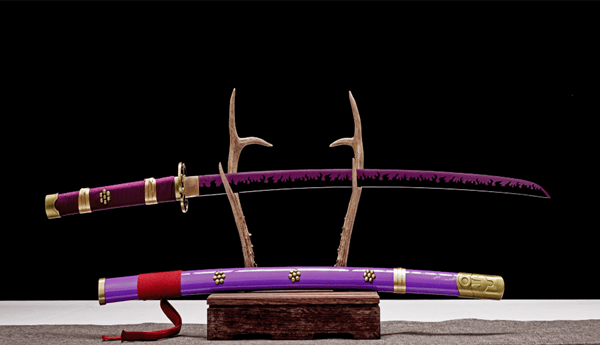

During the 15th and 16th centuries, ninja weapons took a different path than the more famous samurai swords. While samurai blades became curvier and were decorated with fancy techniques, ninja makers cared more about how a blade could be used and hidden. That down-to-earth goal changed every part of the sword, from its mostly straight edge to its shorter size.

Crafting Ninja Blades

To build a true ninja sword, craftsmen borrowed some old Japanese smithing tricks but changed them to fit a simple rule: the weapon had to work first, then please the eye. Skilled ninja smiths skipped the fancy curves and concentrated on a quick, solid build that samurai workshops rarely tried.

Choosing the right steel was the next choice that mattered. Instead of using softer, layered metal that looked beautiful when polished, makers picked harder, tough alloys meant to take stains, dents, and rough use. Without the delicate folding patterns that made a katana sparkle, the ninja blade stayed reliable by having a plain but effective edge for slipping through armor, cutting quickly, or acting like a camp tool.

Even the grip showed that the weapon was more than just a sword. Many had hollow handles where a blade’s owner could stash climbing spikes, tiny smoke bombs, or even a pouch of quick poison for fast surprises. Creating such a compartment was tricky work, since too much weight in the handle could throw off how a fighter balanced and swung the blade. Only a patient, talented swordsmith could pull it off right.

Keeping the right temperature while forging was key to getting the blade of a ninja sword perfectly straight. Makers had to heat and cool the metal just right so it wouldn’t end up curling the way most traditional Japanese blades do. Pulling that off took years of practice and a deep grasp of how different metals behave.

Why a Straight Blade Works Better

The straight design of a ninja sword came with a bunch of practical benefits that a curved blade couldn’t provide. In the cramped, fast-paced fights typical of a ninja mission, the flat edge allowed for powerful thrusts and could punch through light armor more easily than a bent blade.

Another, even bigger, perk was about hiding the weapon. A straight sword slides neatly inside walking staffs, building beams, or even looks like a farming tool when it has the right finish. Because there are no curves to spoil the line of the weapon, a longer blade can be tucked away in places that would never fit a sabre or katana.

The linear shape also turned the sword into a handy climbing tool. Ninjas could drive it into a wall as a piton, lever a door open, or rig it into a simple rope-and-pulley system. That flat profile spreads the weight along the whole length, making it way stronger for those strange jobs.

Why Straight Blades Were a Ninja’s Best Friend

When ninjas were out in the field, keeping their gear in top shape needed to be fast and easy. Straight blades made that job a lot smoother. Their simple edge geometry meant a quick touch-up could be done with nothing more than a rough stone and a steady hand. Because the blade didn’t curve, even battle nicks could be fixed on the move—no special tools and no downtime.

Ninja Blades vs. Samurai Katana: A Tale of Two Designs

At the heart of every duel lies a different philosophy, and that difference is clear when you look at the swords. Samurai blades celebrate art and honor, pouring beauty into every line. In contrast, ninja steel revolves around getting the job done as quietly and quickly as possible.

The katana’s graceful curve isn’t just for show. It helps the sword bite deeper during a fast draw and lets a rider deliver brutal slashes while galloping through the dark. Those perks are impressive, but they do make the weapon hard to hide and less flexible. For a shinobi working under cover of night, extra inches of steel can be a glaring problem.

Straight katana variants have popped up in Japan over the centuries, but most ended up hanging on temple walls or being used in tea ceremonies. When ninjas picked up their own versions, it wasn’t to pay tribute to tradition; it was to carve out a blade that fit their mission-first mindset. Function won out over flair, and that choice shaped every job they took on.

If you’ve ever watched a ninja movie, you’ve probably noticed that the villain’s sword looks a little shorter than a samurai’s katana. There’s a good reason for that. Ninja blades usually ran 24 to 26 inches long, while a traditional katana is closer to 28 to 30 inches. That smaller size made it easier for a ninja to slip through narrow doorways or hide a blade under loose clothing, yet the weapon still had enough reach to be deadly in a fight.

The Hidden History of Ninja Weapons

To really get a grip on ninja swords, you have to step away from the romantic image of the samurai forge. Samurai blades were made in enormous steel villages run by famous families, with each hammer strike celebrated as art. In contrast, ninja swordsmiths worked in back rooms or in quiet farms, teaching their craft to a single apprentice and only that apprentice. Because the trade stayed hush-hush, most of what we know comes from old diaries, not public records.

Where a ninja grew up also shaped how his blade looked. In Iga and Koga, two provinces famous for their spies, craftsmen leaned toward straight lines that stopped curves in favor of toughness. That design choice made sense in the thick forests of those regions, where branches could easily snag a longer arc. Elsewhere, different iron deposits led to swords that handled more like early European rapiers, thin yet still sturdy.

Because these blades were made in secret, modern fans sometimes assume they were rough or cheap. The truth is, many ninja swords were marvels of practicality. The smiths blended careful heat treatments with affordable materials so the edge could be repaired quickly in the field instead of needing a prized family heirloom. Reliability, not parade-polished beauty, was the true mark of quality.

Most of what we know about old-school ninja sword-making is still scattered and incomplete. Because the ninja worked in secrecy and often operated behind enemy lines, records were rarely kept. When they were kept, later generations either hid them or burned them to keep the techniques safe. Yet, pieces of information that have survived hint at a bold approach to weapon design that pushed traditional Japanese sword-making rules aside.

Expert Views on Ninja Blades

Today, martial arts historians and sword specialists are piecing that story together. Dr. Stephen Turnbull, a well-respected voice in Japanese military studies, puts it simply: “The ninja sword’s straight edge showed that duty, not decoration, came first. It worked exactly as stealth jobs needed.”

Modern smiths who spend time studying old ninja gear say the same thing. They keep finding clever metalwork and design choices hiding behind the sword’s plain appearance. What looks basic on the surface often hides curves, angles, and weight distributions that let the blade do many different jobs.

Archaeological digs at old ninja outposts back this up. Excavated weapons show features like adjustable hand guards, thinner tangs for faster draw, and grooves that helped clear rainwater. These findings prove that the smiths had a sharp eye for heat treatment, balance, and the art of combining multiple uses into a single tool.

Master craftsmen who make replicas of old ninja blades say that getting the feel and balance of a straight sword just right takes years of practice. Since the blade doesn’t curve like many other swords, the way the weight is spread and the shape of the cutting edge must be worked out with nearly mathematical care if the weapon is going to perform the way the user expects.

Looking at the Bigger Picture

The reason ninja swords are made straight instead of curved comes from the way these warriors fought. Ninjas weren’t only samurai in disguise; they operated with a whole different set of goals and tactics. Their gear—including every pocket in their clothes—was built for sneaking, slipping through shadows, and vanishing before anyone could call for help, not for standing in the open and trading blows.

Because every job was different, the tools had to change too. When a ninja was sent to gather secrets, he needed something he could hide under a simple jacket; when the goal was to disable a lock or cut through supplies, he required a blade that could pry or poke just as easily as it could slash. The straight sword met both challenges without losing its edge in either situation.

Psychology also mattered. Seeing a blade that looks simple and old-fashioned could make an opponent underestimate who they were dealing with, and that tiny mistake often opened the door for a swift escape—or a quiet victory.