As industries worldwide strive for greater efficiency and sustainability, innovative materials and designs for industrial packaging have become increasingly important. Packaging equipment suppliers are at the vanguard of this movement, relentlessly pushing the envelope with new technologies and materials that significantly enhance packaging efficiency, sustainability, and product safety.

Advancements in Packaging Materials

A major shift in the industry is the development of new materials by packaging equipment suppliers. They are pioneering the use of sustainable resources such as bioplastics, which are made from biological substances rather than petroleum-based plastics. Moreover, there is a growing emphasis on using materials that are not only strong and durable but also recyclable or compostable. Such materials are designed to lessen the environmental impact and cater to the rising consumer demand for sustainable products.

Cutting-edge Design for Maximum Protection

Modern packaging designs prioritize the protection of goods while striving to minimize material waste. Innovations such as improved barrier films, multi-functional layers, and smart packaging technologies that incorporate sensors for tracking the conditions of the product are increasingly commonplace. Innovative designs also focus on modularity, allowing for flexible packaging sizes and shapes, which results in improved logistics and reduced transportation costs.

Enhancing Operational Efficiency

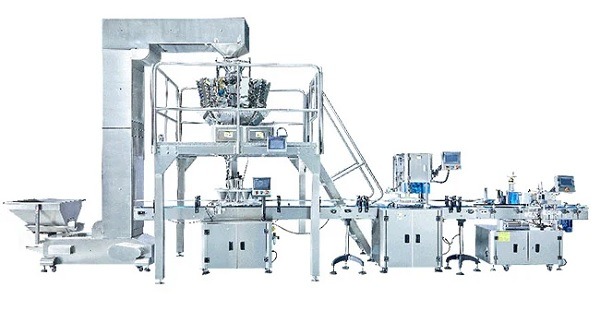

Efficiency is the cornerstone of industrial packaging, and suppliers are continually engineering solutions that streamline packaging processes. Automated packaging lines, for instance, integrate various functions from filling, sealing, to labeling, thus speeding up production without compromising the packaging quality. By leveraging robotics and AI, these suppliers ensure that the machinery they provide can adapt to a range of products and packaging needs with minimal manual intervention.

Embracing Sustainable Packaging Practices

The role of packaging equipment suppliers extends beyond providing immediate packaging solutions. There is a growing trend toward adopting practices that look at the long-term environmental impact of packaging. This includes creating materials and designs that are not only resource-efficient but also fully recyclable, reducing the lifecycle impact of packaging materials.

Customized Solutions for Industry-specific Packaging Needs

Different industries have unique packaging requirements, and suppliers are increasingly providing customized solutions to meet these needs. Whether it’s a capping machine factory designing systems to handle various cap sizes and shapes or the development of specialized cushioning materials for fragile items, the goal is to offer clients a tailored approach that addresses their specific packaging challenges.

In conclusion, packaging equipment suppliers are the backbone of industrial packaging innovation, continually developing materials and designs that meet the twin objectives of operational efficiency and sustainability. As the industry moves forward, these advancements will not only shape how products are protected and displayed but will also play a critical role in reducing the environmental footprint of packaging across the global supply chain. The future of industrial packaging looks promising, with smarter, more sustainable solutions on the horizon.