Two invisible forces quietly power countless processes that shape our daily lives. Compressed air and vacuum systems, often overlooked by the general public, serve as the circulatory system of contemporary manufacturing, enabling everything from the smartphones in our pockets to the automobiles we drive. These pneumatic technologies have evolved far beyond simple air compressors, becoming sophisticated systems that deliver precision, efficiency, and reliability across diverse industrial sectors. Understanding their applications reveals the remarkable ingenuity behind the products and services we depend upon every day.

1. Automotive Manufacturing

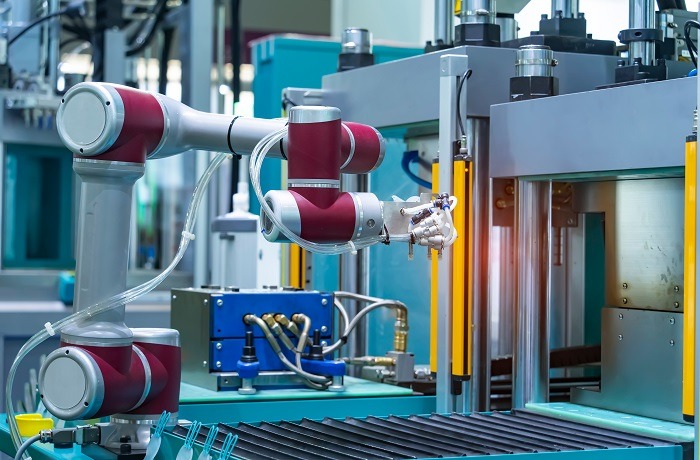

The automotive industry represents one of the most comprehensive applications of compressed air and vacuum systems in modern manufacturing. Throughout vehicle assembly lines, pneumatic systems power robotic arms that perform intricate welding operations, apply paint with microscopic precision, and handle delicate components with the gentleness of human hands yet the consistency of machines. Compressed air drives the pneumatic tools that install thousands of fasteners, while vacuum systems lift and position heavy body panels with millimeter accuracy.

Perhaps most critically, these systems enable the operation of automated quality control equipment that ensures each vehicle meets stringent safety standards. The paint booth process alone relies on compressed air to atomize paint for flawless finishes while vacuum systems capture overspray, maintaining environmental compliance and workplace safety.

The success of these applications ultimately depends on partnering with reputable providers like Air and Power that bring years of specialized experience to the table. They ensure optimal performance and reliability of compressed air and vacuum systems across automotive manufacturing and other industries.

2. Food and Beverage Processing

Within the food and beverage industry, compressed air and vacuum systems maintain the delicate balance between efficiency and safety that consumers take for granted. Vacuum packaging systems extend shelf life by removing oxygen that would otherwise spoil products, while compressed air powers conveyor systems that move products through processing lines without contamination. Pneumatic systems control valves and actuators in brewing processes, ensuring precise ingredient mixing and fermentation control. The dairy industry particularly depends on vacuum systems for milk collection and processing, where maintaining sterile conditions is paramount.

These applications require specialized oil-free compressors and food-grade materials, demonstrating how these systems adapt to meet industry-specific requirements while maintaining the highest standards of hygiene and safety.

3. Electronics Manufacturing

The electronics industry showcases some of the most sophisticated applications of compressed air and vacuum systems, where precision is measured in micrometers and cleanliness standards rival those of medical facilities. Pick-and-place machines that assemble circuit boards rely on vacuum systems to handle components smaller than a grain of rice, positioning them with accuracy that would be impossible through mechanical means alone. Compressed air provides the power for pneumatic actuators that operate at lightning speed during high-volume production runs. Clean, dry compressed air is essential for preventing contamination during semiconductor manufacturing, where even microscopic particles can render expensive components useless.

These systems also power the pneumatic tools used in final assembly and testing, ensuring that the electronic devices we depend on daily meet exacting performance standards.

4. Pharmaceutical Production

Pharmaceutical manufacturing represents perhaps the most demanding application environment for compressed air and vacuum systems, where product purity can literally be a matter of life and death. These systems power tablet pressing machines that create precise dosages, while vacuum systems remove air from packaging to extend medication shelf life and prevent contamination.

Compressed air drives the pneumatic conveying systems that transport raw materials and finished products through sterile environments without human contact. The stringent regulations governing pharmaceutical production require these systems to meet medical-grade standards, with detailed documentation and validation procedures that ensure consistent performance.

Vacuum systems also play a crucial role in research and development laboratories, where they enable processes ranging from solvent evaporation to freeze-drying of sensitive compounds.

5. Material Handling and Packaging

Modern logistics and packaging operations depend heavily on compressed air and vacuum systems to maintain the rapid pace of contemporary commerce. Pneumatic conveying systems transport everything from flour in food processing plants to plastic pellets in manufacturing facilities, moving materials efficiently without mechanical wear or contamination risks. Vacuum lifting systems handle packages and products of various sizes and weights, from delicate glass containers to heavy industrial components. These systems enable the high-speed packaging lines that make modern retail possible, controlling everything from bag filling and sealing to label application.

The reliability and speed of pneumatic systems have become essential for meeting consumer expectations for product availability and delivery times.

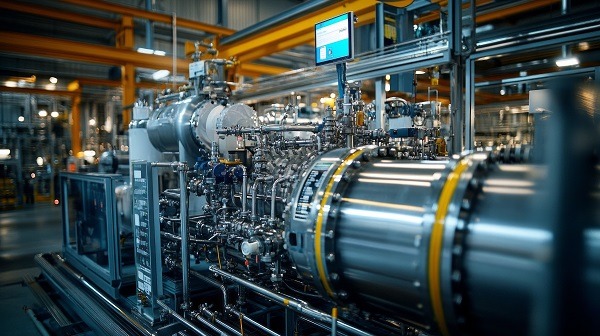

6. Chemical Processing

The chemical industry presents unique challenges that highlight the versatility and safety benefits of compressed air and vacuum systems. In environments where sparks could trigger catastrophic reactions, pneumatic systems provide safe alternatives to electric motors for powering mixers, pumps, and valves. Vacuum systems enable distillation processes that separate and purify chemical compounds, while compressed air powers safety systems that can quickly isolate dangerous reactions.

These applications often require explosion-proof equipment and specialized materials that resist corrosion from aggressive chemicals. The inherent safety of pneumatic power in hazardous environments makes these systems indispensable for chemical processing operations worldwide.

7. Textile and Apparel Manufacturing

The textile industry relies extensively on compressed air and vacuum systems throughout the production process, from raw material handling to final garment assembly. Pneumatic systems power looms that weave fabrics with precise tension control, while vacuum systems remove dust and fibers that could affect product quality. In garment manufacturing, compressed air powers pneumatic sewing machines and pressing equipment that shape and finish clothing with professional precision.

These systems also enable automated material handling systems that move fabrics through dyeing and finishing processes without damage or contamination. The speed and consistency provided by pneumatic systems have revolutionized textile production, enabling the fast fashion industry while maintaining quality standards.

Conclusion

Compressed air and vacuum systems embody the sophisticated engineering solutions that enable modern industrial civilization. From the microscopic precision required in electronics manufacturing to the massive scale of automotive assembly lines, these pneumatic technologies provide the power, precision, and reliability that contemporary industries demand. As manufacturing continues to evolve toward greater automation and efficiency, compressed air and vacuum systems will undoubtedly adapt and expand their roles, remaining the invisible foundation upon which modern industrial productivity rests.